Customizing Coarse Calcium Carbonate Specifications for Industrial Buyers

Learn how to customize coarse calcium carbonate for industrial applications: particle size, whiteness, moisture. Tailored custom calcium carbonate for your needs.

https://tankymineral.com.vn/customizing-coarse

Customizing Coarse Calcium Carbonate Specifications for Industrial Buyers

Coarse-grade calcium carbonate (CaCO₃) plays a key role in industries such as construction, plastics, paints, rubber, animal feed, and chemicals. Each sector requires specific input parameters—particle size (coarse mesh), whiteness, moisture, and purity.

This drives demand for custom calcium carbonate, a solution that allows CaCO₃ to be tailored to exact technical requirements, ensuring optimal efficiency and cost control.

Why Industrial Buyers Need Custom Calcium Carbonate

1. Enhanced production efficiency

Every production line requires a specific coarse or fine grade. Incorrect sizing can lead to poor performance, wasted materials, and increased production cost.

2. Consistency in final product quality

For example:

Paint requires high whiteness

Plastics require uniform particle size

Construction materials require hardness and stability

By customizing coarse mesh, manufacturers receive exactly the grade that matches their application—no blending required.

3. Cost optimization

Instead of using a high-grade, overly refined CaCO₃ that exceeds actual needs, buyers can order the perfect-fit grade and save 10–30%.

Customizable Parameters in Industrial Grade CaCO₃

1. Particle size (Coarse Mesh)

This is the most common requirement. Options include:

5–10 mesh – concrete, mortar, construction

20–60 mesh – industrial products, surface processing

100–200 mesh – plastics and rubber requiring coarse but uniform particles

>200 mesh – still available upon request (fine grade)

Customization includes:

Narrow-cut size distribution

Controlled fine-powder content

2. Whiteness Level

Used in:

Paints

Plastics

Putty powder

Paper

Typical customizable whiteness ranges:

90–92% – general industrial use

93–95% – industrial grade CaCO₃ for plastics/rubber

96–98% – premium grade for paint and coating

3. Moisture Level

Moisture directly affects storage and dispersion. Typical specifications:

≤0.2% – plastics, rubber

≤0.5% – putty and dry-mix materials

≤1.0% – general construction

Lower moisture prevents:

caking

poor dispersion

incompatibility with polymers

Production Process of Customized Coarse Calcium Carbonate

1. Raw material selection

High-purity limestone (CaCO₃ ≥ 95%), preferably from bright-white quarries.

2. Primary crushing

Rocks are crushed to 20–50 mm for further processing.

3. Coarse grinding

Hammer mills, jaw crushers, or roll mills reduce material to 5–200 mesh.

4. Particle classification

Vibrating screens or air classifiers ensure uniform sizing and eliminate oversize or overly fine particles.

5. Whiteness & moisture control

Drying processes reduce moisture; whiteness is checked and stabilized before packing.

6. Packaging

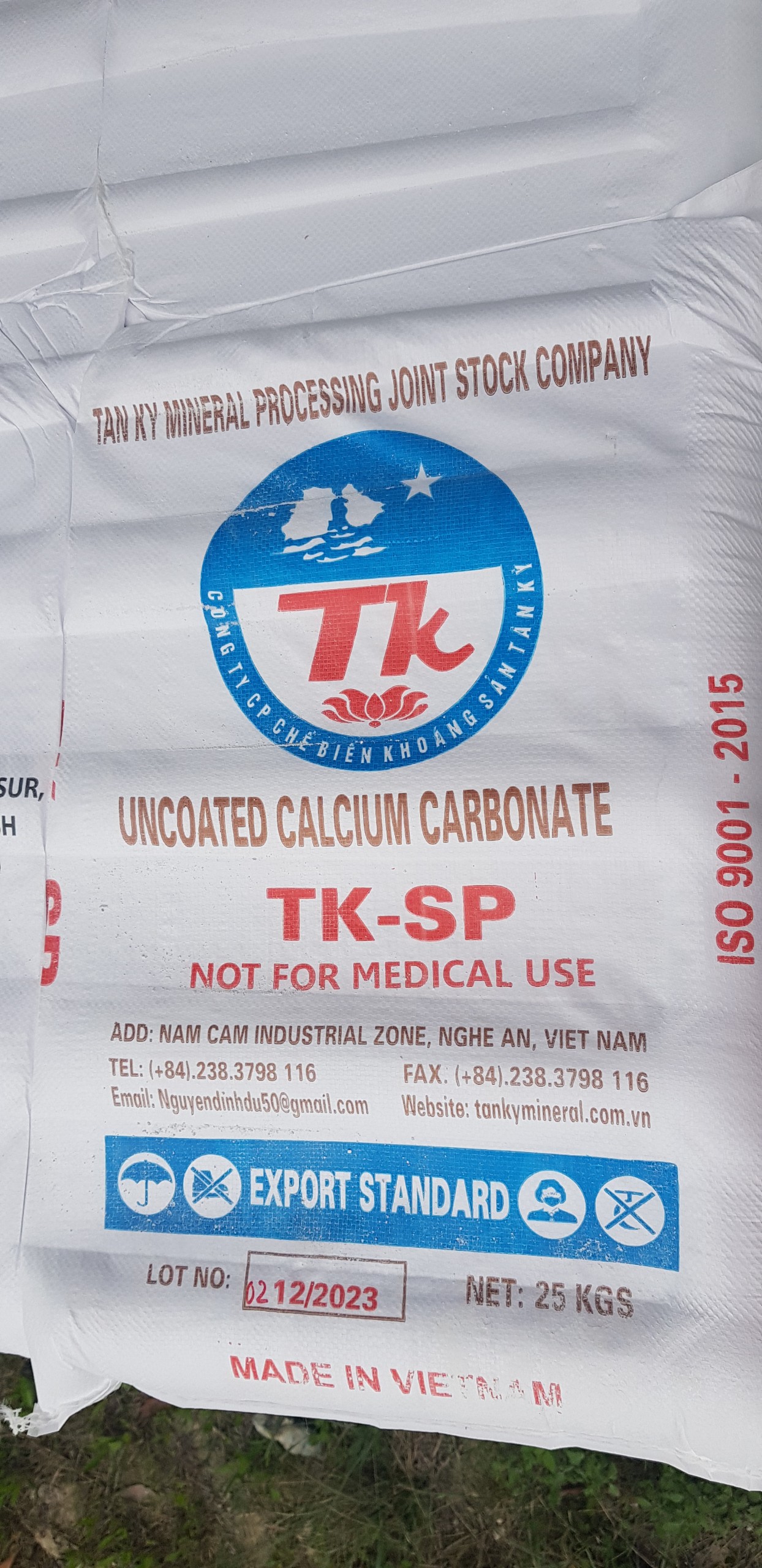

Available in 25 kg / 50 kg PP bags or 1-ton jumbo bags.

Applications of Customized Coarse Calcium Carbonate

Plastics & Rubber

improved rigidity

cost reduction in polymer consumption

dimensional stability

Paints & Coatings

whiteness enhancer

improved opacity

smoother finish

Construction Industry

terrazzo tiles

dry-mix mortars

lightweight concrete

decorative materials

Animal Feed

mineral supplementation

moisture regulation

improved digestion

Benefits of Ordering Custom Calcium Carbonate

Full control over coarse mesh particle size

Consistent and reliable quality

Reduction in waste and downtime

COA and MSDS support

Packaging tailored to logistical needs