Indian calcium carbonate caco3 market 2019

Commoditization of CaCO3 in the Paper, Paints, and Construction Industries has led to Increased Price Sensitivity

Calcium Carbonate is an odorless, colorless and tasteless chemical compound with the formula CaCO3. It is a common substance naturally found in limestone, calcite, aragonite, chalk, marble, pearl and oyster, and can be found in geological, biological and extra-terrestrial sources, including rocks, shells of snails, corals, craters, etc. It is commonly obtained by the means of mining or quarrying, and can also be produced by using calcium oxide as a raw material. Calcium carbonate are used across various industries such as paper, plastics, paints & coatings, personal health, food & beverage, construction, etc. In addition, it is also used in the purification of iron from iron ores, as a filter cake-sealing agent in oil industry, pH control in swimming pools, refining of sugar from sugar beet, filler for latex gloves, neutralising acidic soil and in eradication of harmful sulphuric and nitric acid emissions in fossil fuel power plants by means of process called flu gas desulphurization.

Calcium carbonate has historically been one of the preferred fillers for the paper industry. In recent years, it has also become a preferred filler for the paint industry, heavily substituting kaolin in this application. While the primary reason has been the unavailability of high-quality kaolin, customers are also shifting due to the better opacity, gloss, and scrub resistance provided by calcium carbonate. While paint and paper are likely to remain the main application focus for calcium carbonate, relatively higher growth in segments such as Poly Vinyl Chloride (PVC) and masterbatches offer significant potential for a supplier to target, primarily due to the large expansion plans of companies such as Plastiblends and Finolex in India. Additionally, there is significant import substitution potential for steric coated grades of Ground Calcium Carbonate (GCC) and Precipitated Calcium Carbonate (PCC) in masterbatches and PVC applications.

The key challenge suppliers face today is delivering high product performance in what has become a highly commoditized market. Inclusion of niche grades (such as steric coated for masterbatches and PVC) and application development along with the end user has to be the focus for suppliers looking to make premium offerings and improving their margins. However, this can only be in addition to the high-volume sales of commodity grades, as the potential to make premium calcium carbonate offerings in India remains low.

The demand for PCC is limited by its niche application segments and its price. Even though PCC finds niche usage in applications such as pharmaceuticals and oral care, there are alternate fillers also which are also fulfilling the needs of the respective industry. As a result, GCC accounts for 85% of the calcium carbonate consumed today, while PCC is only 15% of the nearly 3 million MT market size. This market is serviced by 4 large-scale calcium carbonate producers that account for around 30% of the market and an additional 20%–22% of the demand is met by imports. The remainder of the market is fragmented and is catered to by medium, small-scale, and unorganized producers.

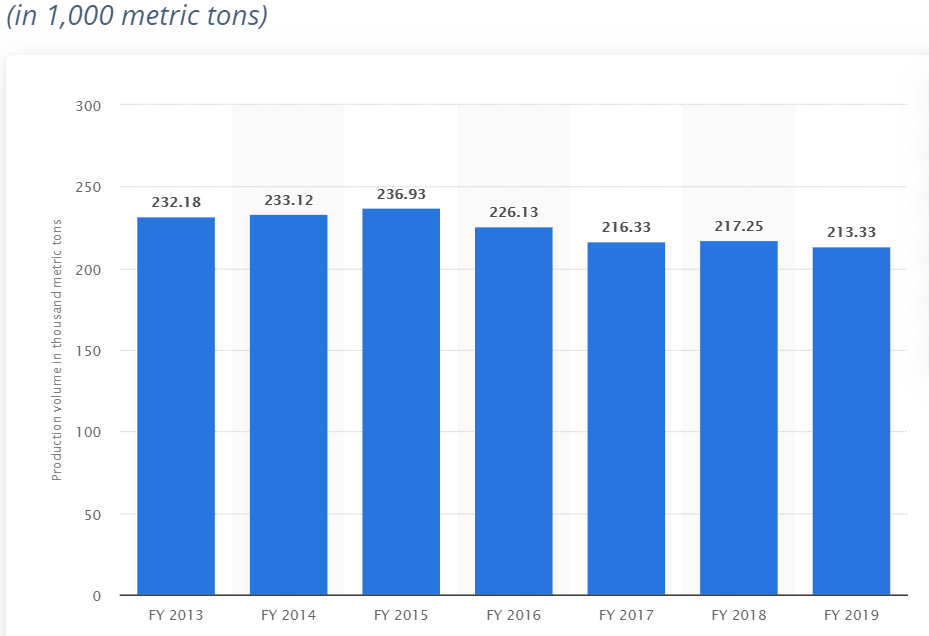

Picture: Production volume of calcium carbonate in India from FY 2013 to FY 2019